NdFeB alloys contain active rare earth elements that oxidize and rust easily. In applications, surface anti-corrosion treatment of NdFeB is required unless NdFeB is encapsulated and isolated from air and water. Common anti-corrosion coatings are nickel plating, zinc plating and electrophoretic epoxy. Surface phosphating treatment can provide rust and corrosion protection for NdFeB for a short period of time in a relatively dry environment.

Rare earth intermetallic compounds can react with hydrogen under certain pressure and temperature. After absorbing hydrogen, NdFeB releases heat and breaks up. Hydrogen fragmentation in the production process of NdFeB utilizes this property of it.

Hydrogen crushing of NdFeB is harmful from a usage point of view.

Strictly speaking, the corrosion of NdFeB starts from its processing. Degreasing after cutting and grinding process, pickling before plating treatment, and plating process all have influence on NdFeB surface layer. Improper processing may result in substandard plating quality (e.g. pinholes), poor bonding between NdFeB surface layer and plating layer, etc.

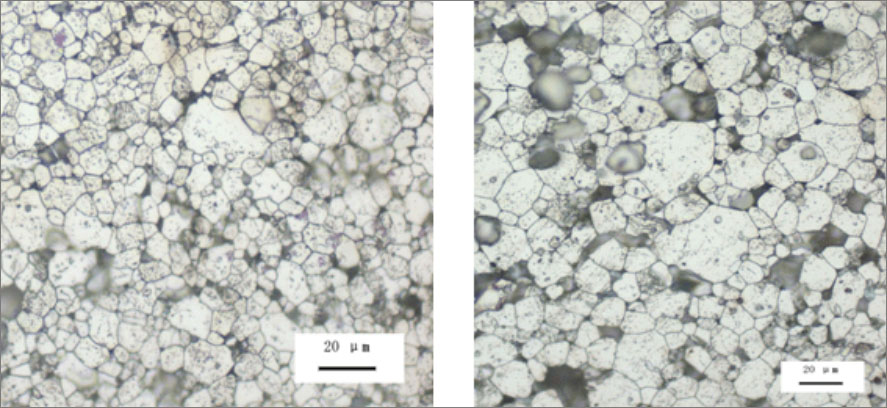

It is worth noting that the same grade of NdFeB magnets produced by different manufacturers, although the magnetic properties are basically the same, but there will be differences in the composition of the alloy, especially the differences in the microstructure of the magnet steel may be very large. Excellent performance, good corrosion resistance of the magnet steel has a fine and uniform grain, the density of the magnet and other characteristics.

Comparison of microstructures of NdFeB magnets (metallographic photographs)

In the above metallographic photographs of sintered NdFeB magnets, the magnets shown on the left have fine and uniform grains, while the magnets shown on the right have large and uneven grains.

Worth knowing;

Neodymium magnet surface coating

Reasons for poor corrosion resistance of sintered neodymium magnets

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier