Wire cutting machine processing NdFeB is a common processing method, especially when precision machining and complex shapes are required, some equipment manufacturers have also developed a number of new wire cutting machines, which bring higher precision and efficiency for NdFeB magnet cutting.

Compared with the traditional wire cutting machine, this machine has many advantages. First of all, it has a higher precision and synchronized multi-axis operation, greatly improving the accuracy of cutting, accuracy of 0.005mm. Secondly, there is a significant increase in cutting efficiency, the equipment can cut at high speed, greatly reducing the production cycle. In addition, the machine has good safety and environmental resistance. Even if there is a wire break during the cutting process, it can be run and handled directly without complicated operation. At the same time, the servo has IP67 protection structure, can withstand the production process of oil, water splashing, reduce the frequency of equipment failure.

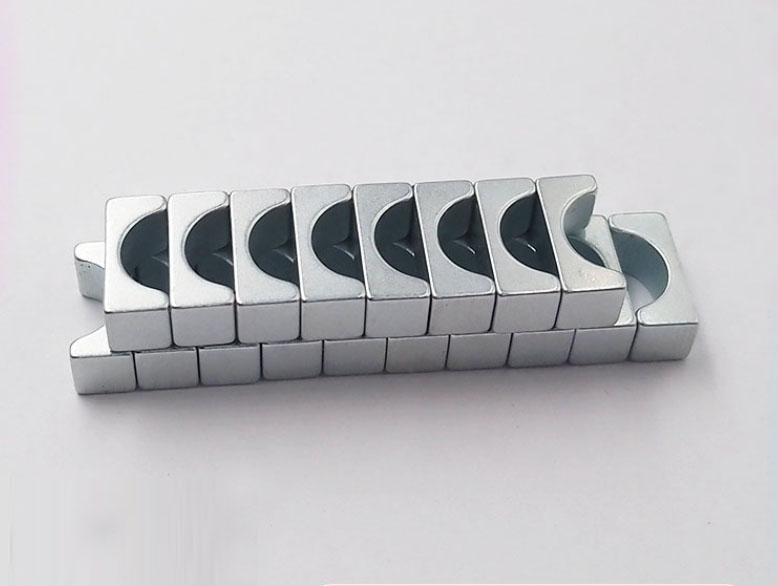

Concave block magnets machined by wire-cutting.

In the actual processing, the staff only needs to fix the magnet to be processed on the working table, and the molybdenum wire on the EDM wire cutting machine will reciprocate at high speed to cut the magnet into the required shape and size. Moreover, the machine can be selected to cut thin sheets or tiles to meet diversified production needs.

Note: EDM wire cutting requires materials with conductivity and non insulating surfaces. Suitable magnets for wire cutting include neodymium magnets, samarium cobalt magnets, aluminum nickel cobalt and other conductive permanent magnets.

More neodymium magnet processing introduction;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier