Ceramic ferrite magnets, as a common permanent magnet material, are commonly used in low-cost products such as speakers, refrigerator magnets, packaging, etc. Can they be used on motor rotors?

The answer is yes. Although the magnetic properties of ferrite magnets are not as good as those of NdFeB magnets, their low cost and good environmental adaptability give them an advantage in some specific motor applications, such as household fan motors, power tool motors, small home appliance motors, toy motors, pump motors, and so on.

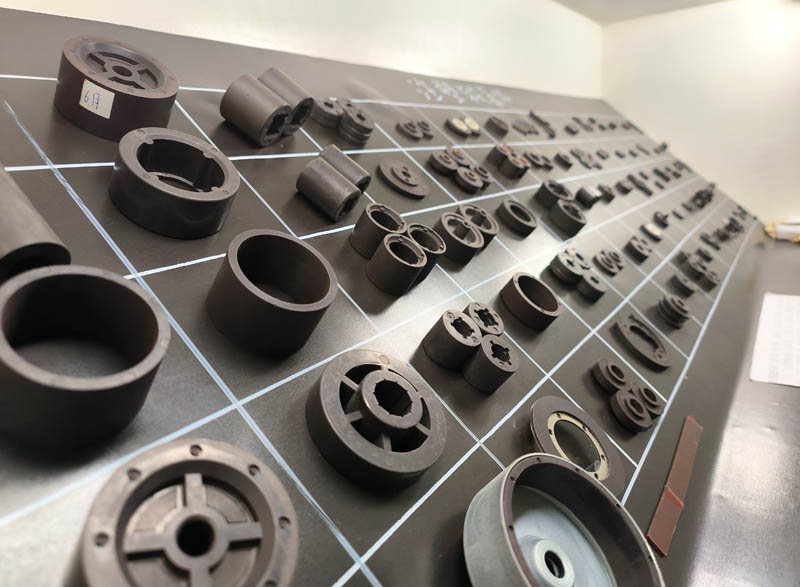

Ferrite rotor magnets can be produced using sintering or injection molding processes, The shapes are predominantly ring, hollow cylindrical and curved (arc).

In the above mentioned motors, ferrite magnets can provide sufficient driving force, corrosion resistance, and low cost make these products more competitive in the market.

Although ferrite magnets perform well in many low-power motors, their magnetic properties are not sufficient for some applications with high power or high performance requirements, e.g., high-speed motors, motors in aerospace equipment, etc. High-performance magnets, such as NdFeB, are often chosen.

Therefore, ferrite magnets can be used in motor rotors, mainly in low-power motors and in environments with high corrosion resistance requirements.

Our company is a professional motor magnet manufacturer, if you have any motor magnet related use, installation, selection, buy sample problems welcome to contact us.

Type of ferrite used in motor rotors;

Other motor rotor magnets are introduced;

Number of motor rotor poles and stator poles

Installation of the rotor magnet for the cooling fan motor

Role of ring magnets on DC motor rotors

Motor arc rotor magnets is too strong how to assemble more safe

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier