Magnets play an indispensable role in modern technology and industrial applications, from simple refrigerator stickers to complex medical equipment and electronic components. One of the performance indicators of magnets is their magnetic field strength, usually measured in Gauss (Gs) or Tesla (T). For many applications, the Gaussian value of a magnet must be maintained within a specific range to ensure its functionality and reliability. Therefore, it is necessary to understand the general tolerance range and influencing factors of the Gaussian value of magnets.

The main factors affecting the gauss value of magnets

This has been described before in related articles, such as the material of the magnet (NdFeB, Ferrite, AlNiCo, etc.), the grade, the manufacturing process (sintered or bonded), the size and shape, and so on.

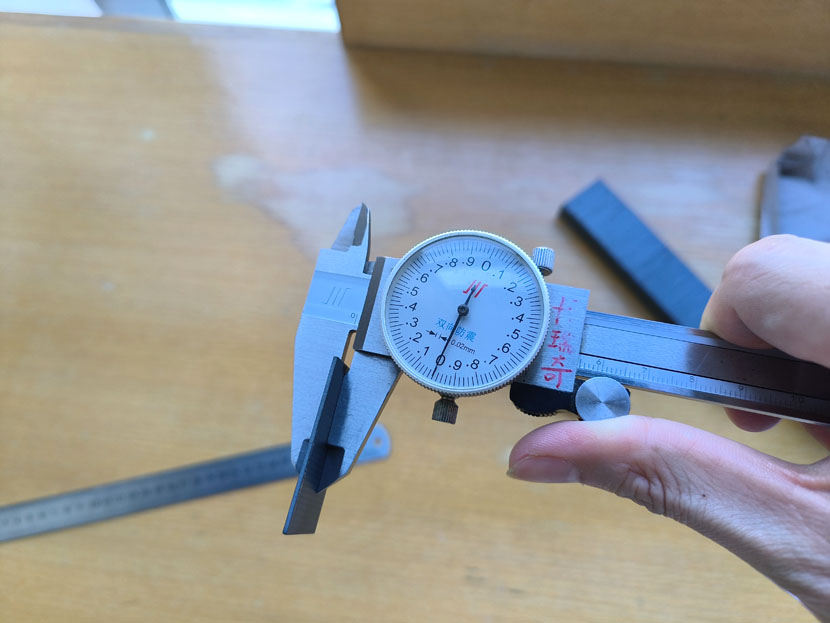

The accompanying figure shows a thin rectangular ferrite, which will also have a low Gaussian value for a thin thickness.

General criteria for gauss value tolerances of magnets

There is no globally standardized Gaussian tolerance for magnets, but rather it is based on specific applications and industry practices.

Surface magnetic field tolerances for powerful magnets like NdFeB are usually around ±20mT (millitesla) or ±200 gauss (±5% to ±10%). For some high-end applications, customers may require tighter tolerances such as ±50 gauss.

Ferrite magnets typically have low residual magnetic induction strengths, with tolerances on gauss values typically ranging from ±10% to ±15%.

The above is the introduction of the magnet gauss value tolerance, although there is no uniform standard, but you can communicate with the magnet supplier, clear tolerance requirements, to ensure that the selected magnet to meet the application requirements.

Different gauss magnets are recommended;

Recommended size for surface 5000-5999 gauss magnets

You might want to know;

How do I calculate Gauss based on magnet grade and size?

How many gauss does a magnet need to qualify?

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier