In modern science and technology and industrial fields, the application of magnetic materials is ubiquitous, arc magnet as one of the special shape of the magnet, widely used in electric motors, industrial equipment and a variety of precision instruments, it is worth noting that these arc magnets are often used in the radial magnetization way, this is how it is?

Definition of Radial Magnetization

Unlike conventional axial magnetization, radial magnetization means that the magnetic field lines are aligned radially outward from the inside of the magnet or radially inward from the outside. In curved magnets, this means that the magnetic field is evenly distributed along the circumference, forming a closed circle of magnetic lines.

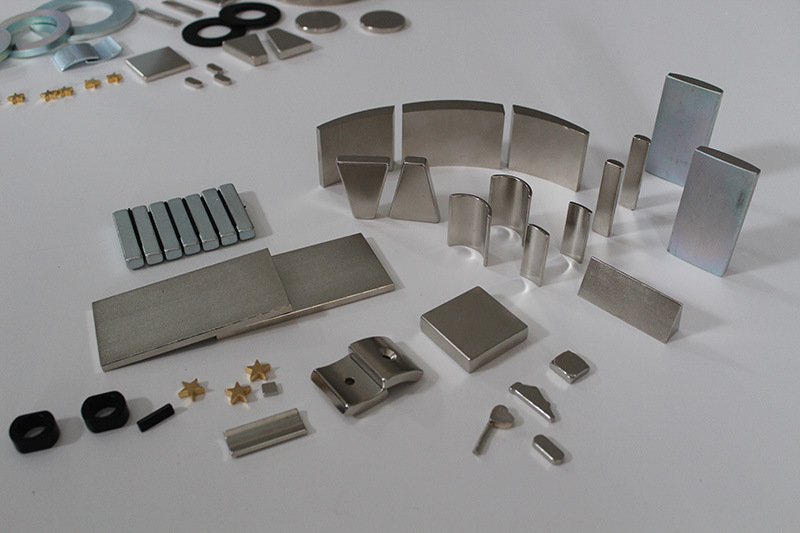

Rare earth neodymium magnets in various shapes and types

Advantages of radial magnetization for arc magnets

Uniform Field Distribution: Radially magnetized arc magnets produce a more uniform magnetic field distribution. This field distribution creates a relatively consistent pattern of magnetic lines of force between the inner and outer arcs of the magnet, which facilitates a consistent magnetic field effect in a given application.

Concentration of magnetic lines of force: Radial magnetization concentrates the magnetic lines of force more than axial magnetization. This concentration effect can provide greater magnetic field strength in certain applications, especially where high magnetic field gradients are required.

Reduced Magnetic Leakage: Radially magnetized arc magnets typically have reduced magnetic leakage due to the increased concentration of the magnetic lines of force. This is important in applications where precise control of the magnetic field range is required.

Suitable for Rotating Systems: Radially magnetized arc magnets are especially useful in rotating systems such as motors and generators. They provide a constant, directionally consistent magnetic field that helps improve system efficiency and performance.

Optimized Space Utilization: Radial magnetization allows curved magnets to achieve maximum magnetic field strength within their limited space. This is critical for space-constrained applications such as miniature motors and precision sensors, ensuring that sufficient magnetic force is still available in a compact design.

Customized magnetic field design: Radial magnetization allows flexibility in designing the shape and intensity distribution of the magnetic field to meet specific application requirements. By adjusting the curvature, thickness and magnetization depth of the magnet, the field characteristics can be precisely controlled to meet specific operating conditions.

The above is about why most of the radial magnetization of arc magnets, our company is a permanent magnet manufacturers, can be customized for you to process a variety of materials, performance levels of neodymium arc segmented magnets, ceramic arc segmented bending magnets, samarium cobalt arc magnets, and so on, the need for quotations, please send an inquiry with us, thank you!

Learn more about arc magnets;

Why are segmented arc magnets so efficient?

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier