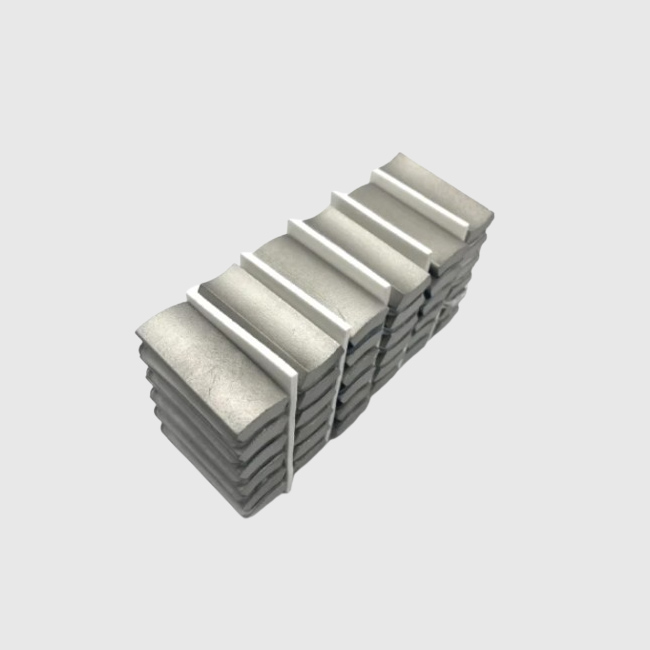

The use of samarium cobalt magnets in motor designs, especially curved ones, offers the following advantages:

Heat Resistance: Samarium Cobalt magnets are capable of operating at temperatures up to 300°C or even higher, which makes them ideal for applications that require them to operate in high temperature environments, such as jet engine fans, motors in industrial heating applications, and more.

Anti demagnetization ability: Samarium Cobalt magnets have strong anti demagnetization ability and are not easy to lose magnetism under high external magnetic field or mechanical shock.

Lightweight: Due to the high energy product of Samarium Cobalt magnets, it is possible to achieve smaller size and weight while maintaining a strong magnetic force, which is especially important for weight-sensitive applications such as aerospace or high-performance electric vehicles.

For curved samarium cobalt permanent magnets used in high-temperature motors, custom manufacturing is often required to match the specific geometry and magnetic performance requirements of the motor. Manufacturers will adjust the composition ratio of Samarium Cobalt magnets (e.g. SmCo5 or Sm2Co17) according to specific application scenarios. Drawings or dimensional data are welcome to inquire about pricing.

The following samarium cobalt article is worth knowing

Magnetization and processes of SmCo rare earth permanent magnets

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier