Our company for motor magnet manufacturers, mainly provide permanent magnets, do not provide glue, but often have a lot of customers ask us what kind of motor magnet glue is better, the following editor to recommend some, hope to help you.

Motor magnet paste is mainly used in the motor magnet (arc magnet/magnetic ring) and the housing or motor rotor and magnetic steel bonding fixed, the following are several commonly used motor magnet glue.

One. acrylic structural adhesive

Acrylic glue forms a strong adhesive layer after curing, but also has a certain heat resistance, mainly used in ferrite and shell bonding, two-component curing speed, high strength, curing colloidal toughness is good, temperature resistance 110 degrees, low cost is mainly used in ordinary DC motors, such as curtain motor, massage chair motor, toy motor and so on.

Two, epoxy resin AB glue

Like AE390 is an imported raw material epoxy resin AB adhesive, after mixing the operation time (90 minutes), can be cured at room temperature or warm fast curing, high bonding strength after curing, good hardness, good toughness and drop resistance, curing good acid and alkali resistance, low shrinkage rate, moisture and waterproof, oil resistance and chemical properties, resistance to humidity and heat and atmospheric aging. Can be applied to most motor magnet material and housing or shaft high strength bonding. Temperature resistance 120 degrees instant up to 150 degrees. It is widely used in automobile motor, rotor and magnetic steel bonding, aircraft brushless motor magnetic strip, external brushless motor wire fixing, brushless hollow cup motor coil and iron core fixing.

Three. Heat resistant polyurethane adhesive

Polyurethane adhesives typically have excellent heat resistance and are suitable for motor applications that require frequent exposure to high temperatures.

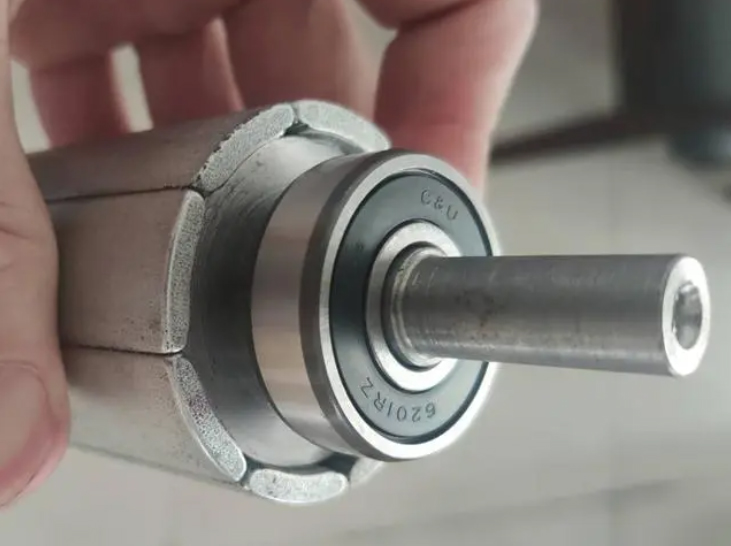

Motor magnet glue fixed arc Neodymium magnets

Four, anaerobic structural glue

Mainly used in ferrite segment magnet and shell, galvanized nickel-plated NdFeb magnet and shell bonding, single component easy operation, fast curing speed (5 minutes of initial curing), high bonding strength, toughness, high temperature resistance 120, instant up to 150 degrees. Widely used in most small and medium-sized DC motors, brushless motors and other magnet bonding.

Note: Regardless of the type of glue used, you should follow the manufacturer's recommendations and regulations to ensure that the appropriate glue is selected and bonded correctly.

Website motor magnet product column direct;

Injection molded neodymium magnets

DC Motor Rotor & Stator Magnets

Related magnet question;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier