In motor design, attaching curved magnets on the outer surface is a common installation method for permanent magnets, widely used in brushless DC motors (BLDC), permanent magnet synchronous motors (PMSM), etc. So, how are the 8-pole curved segment magnets arranged on the outer surface?

Basic concepts of 8-pole externally applied magnetic tiles;

Number of poles: 8 poles means that there are 8 magnetic poles on the surface of the rotor (4 pairs of alternating N-S poles).

Surface-mounted magnetic tile: Magnetic tiles are directly affixed to the outer surface of the rotor core, forming an outer rotor structure (or inner rotor, depending on the type of motor).

Magnetizing direction: The tiles are radially magnetized, with the poles (N/S) of adjacent tiles arranged alternately.

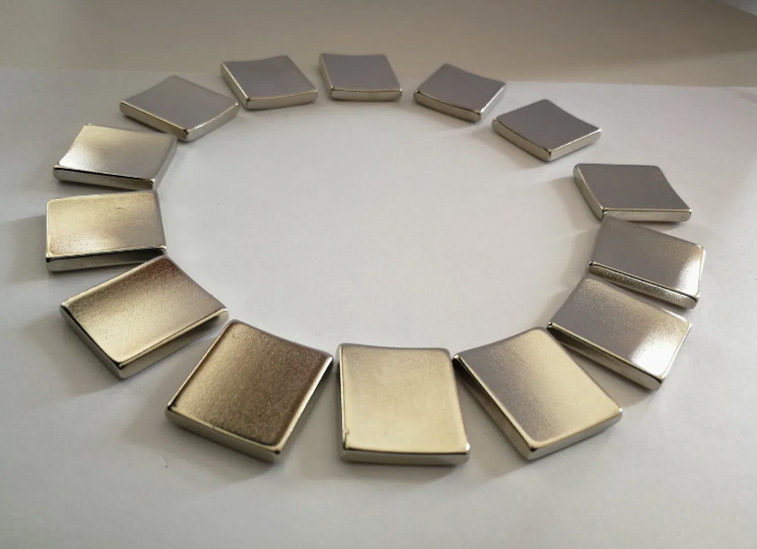

Powerful Arc Tile Segmented Neodymium Magnets

Main Arrangement - Radial Magnetization Arrangement

Eight pieces of curved magnets, each corresponding to a magnetic pole, are required to be uniformly affixed to the circumference in the N-S-N-S-N-S-N-S manner, with adjacent tiles magnetized in opposite directions to form a complete magnetic circuit.

Halbach magnetic array arrangement

With Halbach array structure, the magnetization direction of each tile is arranged at a specific angle, e.g. “N → Oblique N → S → Oblique S → N → Oblique N → S → Oblique S”. Suitable for high-end motors, such as high speed motors and special motors.

The above is the full introduction of the article. After installation, testing is required to confirm that the N/S poles are alternating correctly and that the curved magnets are firmly bonded. The standard radial magnetization arrangement is suitable for most motors, while the Halbach array is suitable for high-end applications.

We are a professional motor magnet manufacturer, if you need to buy rare earth arc magnet, radial multi-pole integral ring, welcome to submit an inquiry.

Types of magnets commonly used in motors;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier