Magnets are widely used in various industries, different environments have different requirements for the corrosion resistance of magnets, in order to ensure the reliability of magnets in different environments, it is usually necessary to do corrosion resistance testing, the following are some common methods.

1. Salt Spray Test

Salt spray test is one of the important tests for neodymium magnets, which is mainly used to evaluate the corrosion resistance of neodymium permanent magnet materials by utilizing the artificial simulated salt spray environmental conditions created by the salt spray test equipment, and there are mainly three kinds of tests: Neutral Salt Spray Test (NSS), Acetate Spray Test (ASS), and Copper Salt Acetate Accelerated Salt Spray Test (CASS).

Salt spray test is mainly used for e.g. nickel-plated, galvanized or epoxy-coated magnets.

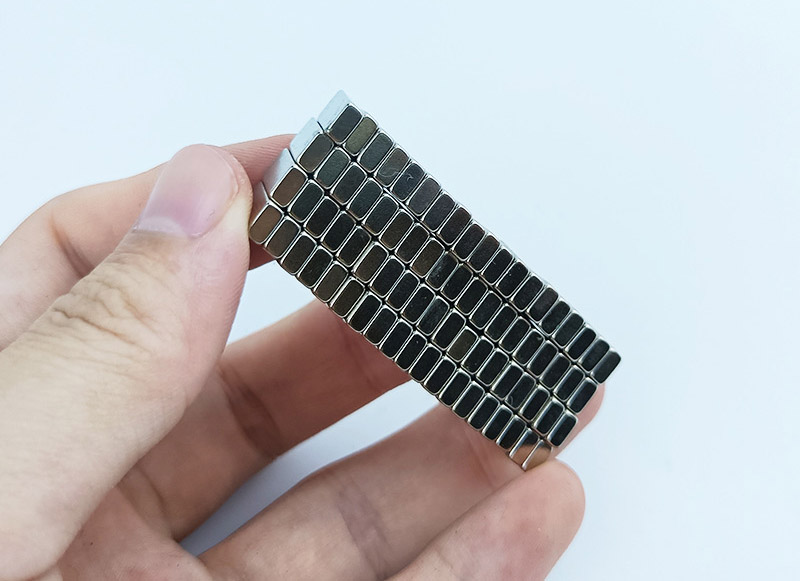

The accompanying picture shows a nickel-plated neodymium block magnets, It is a very common magnet plating.

2. High Humidity Test

The High Humidity Test is used to evaluate the corrosion resistance of magnets in high humidity environments. The test is usually conducted at a relative humidity of 95% or more and a temperature of about 50°C. The test can last from several days to several weeks. By observing the changes on the surface of the magnet, you can determine its corrosion in a humid environment.

Application: For magnets applied in humid environments, such as magnets inside electric motors or magnets in outdoor equipment.

3、Electrochemical corrosion test

Electrochemical Corrosion Test is a method of evaluating the corrosion resistance of magnets by measuring their electrochemical behavior in an electrolyte solution. In the test, a magnet sample is placed in a specific electrolyte solution and a certain voltage is applied to measure its corrosion current density and corrosion potential. This method enables a quantitative assessment of the corrosion rate of the magnet and the protective properties of the coating.

4. Immersion test

The Immersion Test evaluates the corrosion resistance of a magnet sample by immersing it in different corrosive media (e.g. acid, alkali or salt solutions) and periodically checking the surface changes and weight loss of the sample. The pH and temperature of the test environment can be adjusted according to the actual application requirements.

This test is suitable for magnets that need to work in specific chemical media for a long period of time, such as magnets in chemical equipment.

These are just a few of the general test methods for corrosion resistance of magnets, thanks for reading.

Highly relevant content;

How many hours of neodymium magnet nickel plating salt spray?

How many hours of salt spray test can galvanized neodymium magnets pass?

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier