I don't know if you have found, some magnets will have chamfered edges to deal with, the advantage of doing so is to remove the sharp corners or sharp corners, you can better protect the magnets, at the same time, safer to use, so the general round magnet chamfering how big it is?

Common dimensions for round magnets with rounded corners

For small round magnets (<10mm), NdFeB is more common, and its chamfer is usually small, R 0.1mm, R 0.2mm or so.

For medium size magnets (between 10mm and 30mm in diameter), it is usually chamfered at R0.2 - R0.5mm.

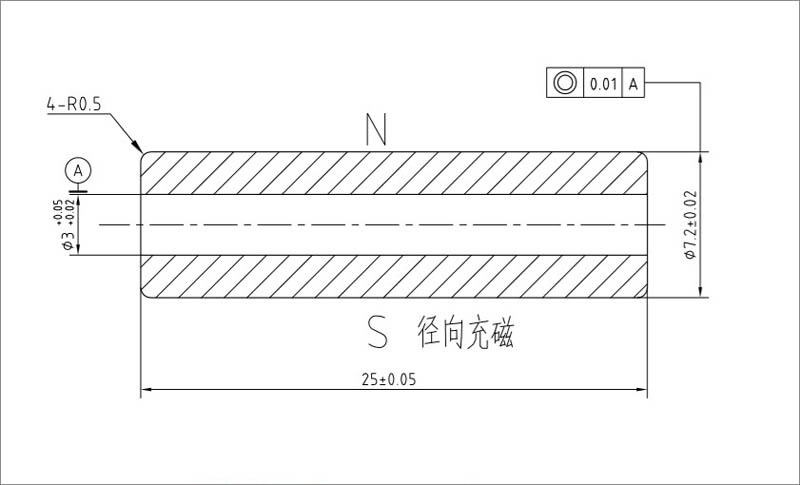

The picture shows a hollow cylindrical magnet with 0.5mm chamfered R angle.

For round magnets with a diameter of more than 30 mm, the chamfer size may be larger.

It should be noted that the larger the radius of the chamfer, the smoother the appearance of the magnet, but it also affects its magnetic properties and production costs.

The exact size of the chamfer is not set in stone, but is influenced by a number of factors. For example, in some precision instruments, magnets are chamfered to a smaller size to avoid affecting magnetic properties, while in magnets for industrial use, the size of the chamfer may be slightly larger to improve assembly reliability.

The chamfering of round magnets is not only for the sake of aesthetics, but also an important measure to ensure the performance, ease of installation, safety and long-term use of magnets. The design of appropriate chamfering size can effectively improve the performance and reliability of the magnet, so in the design and manufacture of magnets, chamfering should be adjusted according to the actual application requirements.

Written in the end, before the magnet plating, magnet manufacturers will use the chamfering machine to chamfer the magnet, which can make the current distribution more uniform, and help to form a more uniform and stronger plating layer.

Related chamfered magnets;

Round ferrite magnets with dots and chamfers 17.8x7.8mm

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier