The“code channel”in an encoder refers to the signal channel on the encoder that is used to detect rotational or linear displacements. Currently, the main types of encoders used are single, dual, and triple code channels, etc. When selecting a code channel material for an encoder, several factors need to be considered, including environmental conditions, application requirements, and cost.

Types of magnet materials commonly used in encoders;

The magnet materials commonly used for encoder code channel are injection molded magnets and rubber magnets, which have different characteristics and applicability, the following are the advantages and disadvantages of these two materials in order to help you make a better choice.

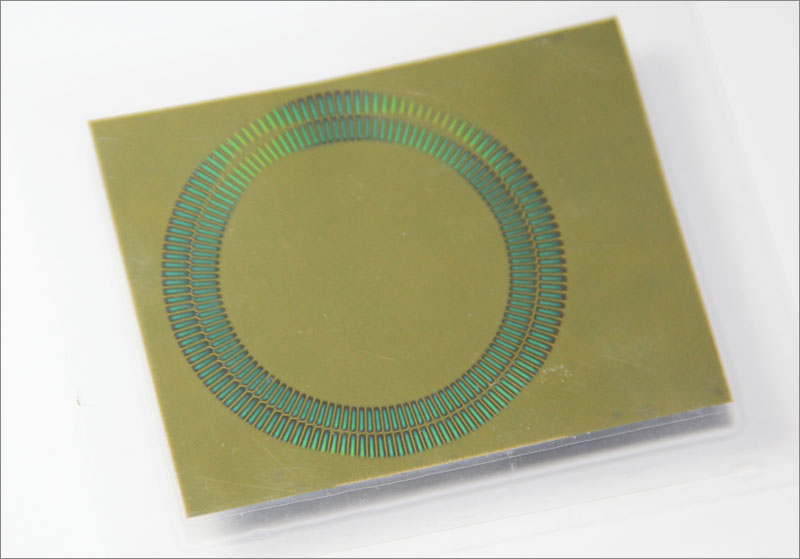

Magnetic encoder dual-channel magnetic rings, Uses dual gauge magnetization that can be customized for many applications.

Let's start with injection molded magnet, injection molded magnet is a method of molding magnetic materials through injection molding process, there are injection molded ferrite and injection molded neodymium magnets. It has high magnetic properties and magnetic stability, and can provide high signal resolution and stable output, such as motor control, robot positioning and so on.

Its main advantage is that it can be made into complex shapes with high dimensional accuracy, which makes it suitable for encoders with complex designs, and is especially suitable for applications requiring durability and impact resistance.

Rubber magnet (e.g. bonded ferrite) is a kind of material formed by mixing magnetic powder into rubber substrate, which has good softness and elasticity, and can adapt to certain surface shapes and bending, the production process of rubber magnet is relatively simple and low cost.

The choice of injection molded magnets or rubber magnets for encoder code channels depends on the specific application requirements. If a high accuracy and high resolution encoder is required, injection molded magnets may be more suitable; if there are high requirements for flexibility and cost, rubber magnets may be a better choice. In practical applications, it is also necessary to consider the material properties, production process, cost and other factors to make the most suitable choice.

Correlated magnetic encoder magnets;

Robot Encoder Dual-Channel Magnetic Ring 56x38x1.1mm

Magnetic encoder multipole ring magnet 62 64 pole OD 34mm

Multipole double coil rubber magnetic ring for encoder D49x25x2mm

Recommended Reading;

Function and Application of Magnets in Encoders

How to check the number of magnetic poles on the encoder ring?

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier