We all know that magnets are widely used in electronics, industry, equipment, instruments, scientific research, etc. What happens in salt water? Will it work properly? Will the magnetism decline? Here is the answer of Xiao Fu.

Magnets work well in salt water

Salt water is an electrically conductive medium, consisting mainly of water and salts. When a magnet is placed in salt water, the magnetic field is not disturbed much because the magnetic field can penetrate most non-conductive materials, including water, air, and plastic. The salt water itself does not weaken the magnetic field, so the magnet's magnetic force is maintained in the salt water.

However, due to the electrical conductivity of salt water, magnets may be affected by galvanic corrosion when working in salt water. The salt in salt water accelerates oxidizing reactions on metal surfaces, especially when magnets are exposed to high salinity environments where the corrosion rate increases significantly. Therefore, while the magnet's magnetic properties are not directly affected by salt water, its life and performance may be shortened by corrosion.

In salt water or seawater environment, if you need neodymium iron boron magnets, usually need to do adhesive sealing treatment, this can better protect the magnet.

Magnets of different materials behave differently in salt water

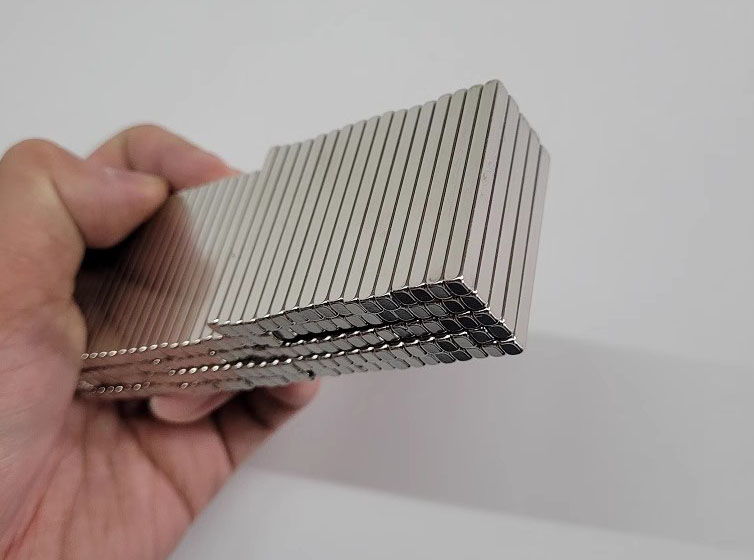

Take NdFeB magnet as an example, it is the strongest permanent magnet at present, widely used in high performance magnetic products. However, NdFeB magnets have poor corrosion resistance in salt water and are highly susceptible to salt water corrosion. Therefore, when applied in marine environment, NdFeB magnets need special surface coating or non-metallic material wrapping.

Alnico magnets have better resistance to corrosion and high temperatures, so they perform better than NdFeB in salt water. However, Alnico magnets have a weaker magnetic force and may be less suitable in applications requiring strong magnetic fields.

Ferrite magnets have good resistance to corrosion, especially in wet environments and salt water. Although ferrite magnets are weak, they are inexpensive and corrosion-resistant, and are commonly used in marine equipment where strong magnetism is less emphasized.

Samarium Cobalt magnet is a magnet material with excellent corrosion resistance and stable performance especially at high temperatures and in harsh environments. Despite its high price, it is often used in marine applications where high durability and corrosion resistance are required

Some of the application scenarios;

In practical applications, magnets are widely used in saltwater, such as marine exploration and navigation equipment, magnetic water treatment systems, medical and biotechnology, fisheries and aquaculture, etc. Due to the corrosive nature of saltwater on magnets, samarium cobalt magnets with strong corrosion resistance or neodymium iron boron magnets coated with corrosion-resistant coatings are usually used.

Introduced here, we know that magnets can work in seawater, but their use effect is closely related to magnet materials, seawater environment and anti-corrosion treatment. Selection of appropriate materials and anti-corrosion measures can extend the service life of magnets in the marine environment and ensure the stability of their performance. In practical applications, NdFeB magnets require good anti-corrosion measures despite their strong magnetic properties; while samarium cobalt magnets and ferrite magnets are quality choices for some marine applications.

Associated waterproof coated magnets;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier