In the field of electric motors, magnetizing the rotor is a crucial process, which directly affects the performance, efficiency, and life of the motor. Regarding the choice of waveform for rotor magnetization, sine wave and square wave are two common ways, the following is your concern about whether it is better to magnetize the rotor with sine wave or square wave? How to choose the introduction.

Introduction to Sine Wave Magnetization

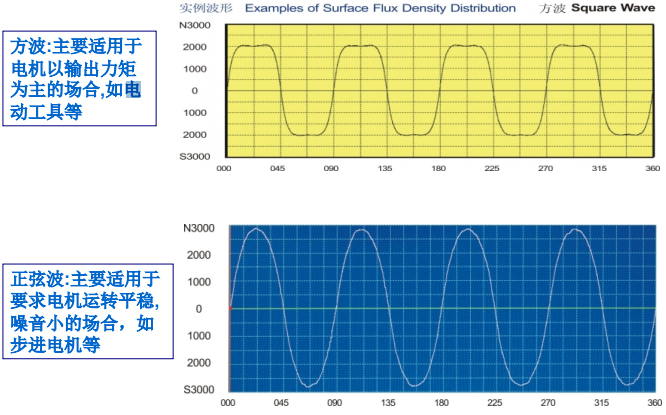

The main advantage of sine wave magnetization is its smooth waveform, which reduces the harmonic content of the motor's operation, thus improving its efficiency and operational stability. Sine waveforms produce smooth and continuous magnetic field changes during the magnetization process, which helps to reduce vibration and noise in motors. In addition, motors driven by sine wave typically have a high power factor, which means lower energy losses and higher energy efficiency. They are usually more suitable for applications that require smooth motor operation and low noise, such as stepper motors and servo motors.

The attached figure shows examples of waveform diagrams for sine and square waves;

Square wave magnetization

In contrast, square wave magnetization offers high drive efficiency and low control cost. Due to the relative simplicity of generating and controlling square waves, the drive circuits are less expensive to design and implement. This gives square-wave magnetization an advantage in some cost-sensitive applications. In addition, square wave-driven motors have better starting performance and can provide larger starting torque, which is suitable for applications requiring fast response and large torque output, such as power tools, certain types of brushless DC motors (BLDC), etc., and is not suitable for environments with stringent requirements for noise control.

Like the three-wheeled electric car recommended the use of positive Xuan wave motor, its current changes more gently, which is conducive to reducing the damage to the motor, thus improving the service life of the motor, and at the same time, due to the smooth change of the current, the motor's operating noise is also relatively small.

Therefore, sine wave and square wave magnetization have their own advantages and disadvantages, there is no absolute good or bad, the key lies in the specific application requirements to determine the most suitable magnetization waveform. If the pursuit of motor operation smoothness, low noise and high precision control, sine wave magnetization is a better choice; if you need a strong torque output and high power density, square wave magnetization is more appropriate.

Related Motor Rotor Magnets categories;

Introduction to related rotor magnets;

How to embed arc magnet on the outer surface of the motor rotor?

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier