Ring one-piece magnets are widely used in all kinds of motors and magnetic devices, it has some significant advantages, but also has certain disadvantages, this paper will synthesize these features, the ring one-piece magnets are analyzed in detail.

Advantages: easy to assemble, low cost

One of the biggest advantages of the Ring One Piece Magnet is its ease of assembly. Due to its simple structure, the installation process is very efficient and does not require complex processes or time investment.

Ring magnets are usually made of bonded NdFeB or injection molded ferrite, both of which are relatively inexpensive to produce. As a result, products using ring magnets have a cost advantage and are particularly suitable for price-sensitive markets.

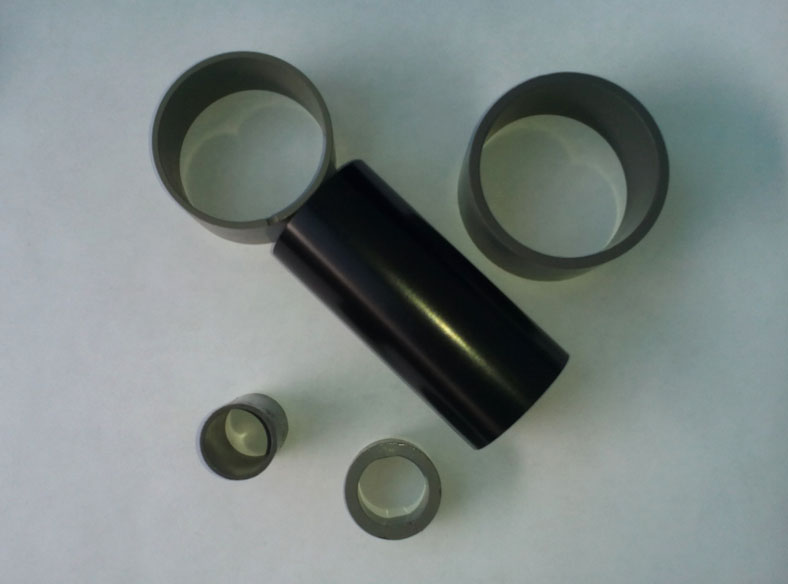

Ring Magnets - Bonded Molded Neodymium Material

Suitable for low and medium speed motors. For motors with a typical speed of around 5000 rpm, the magnetic properties of ring magnets are sufficient. This makes ring magnets a cost-effective option, especially in application scenarios where excessive magnetic properties are not required.

Ring magnets are generally bonded NdFeB and injection molded ferrite, which have lower magnetic field strength compared to high performance sintered NdFeB magnets. Ring magnets made with sintered NdFeB have better magnetic properties compared to bonded NdFeB or injection molded ferrite magnets.

The slightly higher cost of sintered NdFeB relative to tile-designed magnets may make other low-cost materials an option in some cost-sensitive products. However, this cost outlay is worthwhile considering its stronger magnetic properties.

The specifications and magnetizing effect of ring magnets are the key factors affecting their performance. Common ring magnets range in diameter from 14mm to 70mm, and the number of magnetized poles is usually 8, 10, or 12 poles. Depending on the specific needs, multi-pole ring magnets with different diameters, aspect ratios and wall thicknesses can be produced.

Now, the ring sintered NdFeB magnets are also in great demand in the market, also called radiation ring magnets, some domestic and foreign large customers are in bulk use.

Similar articles;

Types and advantages and disadvantages of NdFeB multipole magnetic ring

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier