The quality of motor magnets (usually referred to as permanent magnets used in permanent magnet motors) is directly related to the performance, efficiency and life of the motor. Therefore, in the process of production and use, it is very important to carry out strict testing of motor magnets, and the key testing items mainly include the following aspects.

Magnetic flux consistency

Magnets as a motor rotor or stator magnetic field source, if there is a difference in consistency, will cause motor vibration, power reduction and thus affect the overall motor function, so the motor magnets are generally required for flux consistency, some require 5% or less, some require 3% or even 2% or less, for the factors affecting the consistency of the flux should be taken into account, such as residual magnetism consistency, tolerance consistency, and the consistency of chamfering Factors affecting the consistency of magnetic flux should be taken into consideration, such as the consistency of residual magnetism, tolerance consistency, and chamfering.

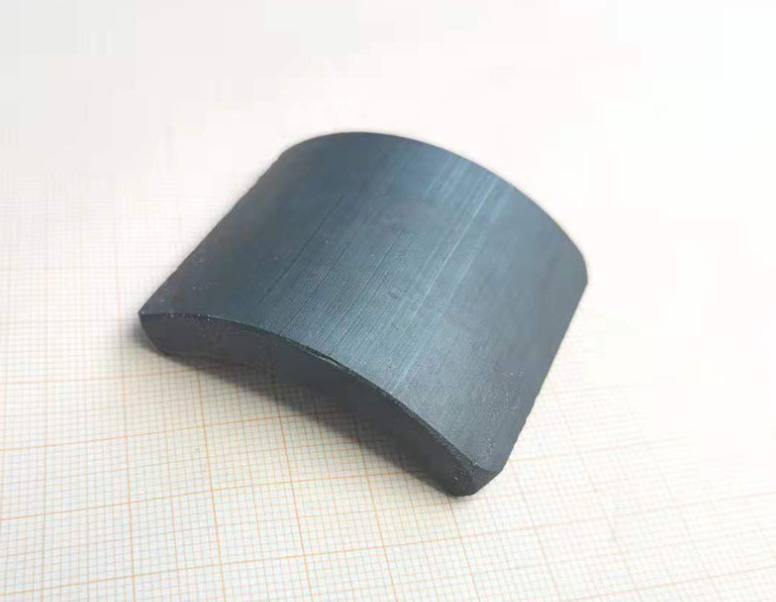

Arc Segmented Ceramic Magnets for Micromotors, High performance, high speed motors generally use neodymium arc magnets.

Precise physical dimensions:

The physical dimensions and tolerances of the magnets, such as outer radius, inner radius, width, height, etc., are in accordance with the technical requirements of the drawings, which ensures the overall performance of the motors and assembly precision.

High temperature stability

Some customers will require the measurement of open circuit magnetic decay, some customers will require the measurement of semi-open circuit magnetic decay, motor operation magnet steel in addition to withstand high temperatures but also to withstand the alternating reverse magnetic field, so the magnetic decay of the finished product, the substrate high-temperature demagnetization curve is a must to test and monitor.

Adaptability

The surface mounted magnetic steel is mainly arc-shaped. The conventional anime test method for angle and radian has large errors or is difficult to test. At this time, its adaptability needs to be considered. Some closely arranged magnetic steel needs to control the accumulated gaps, and some dovetail slot surface mounted magnetic steel needs to consider the tightness of the assembly. It is best to make profiling fixtures according to the user's assembly method to test the adaptability of the magnetic steel.

These tests ensure that the quality and performance of the motor magnets meet the requirements of the application.

More knowledge about motor magnets;

Motor stator magnet working principle

Brushless motor magnet arrangement and spacing

Number of Magnet Magnetization Poles and Motor Speed

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier