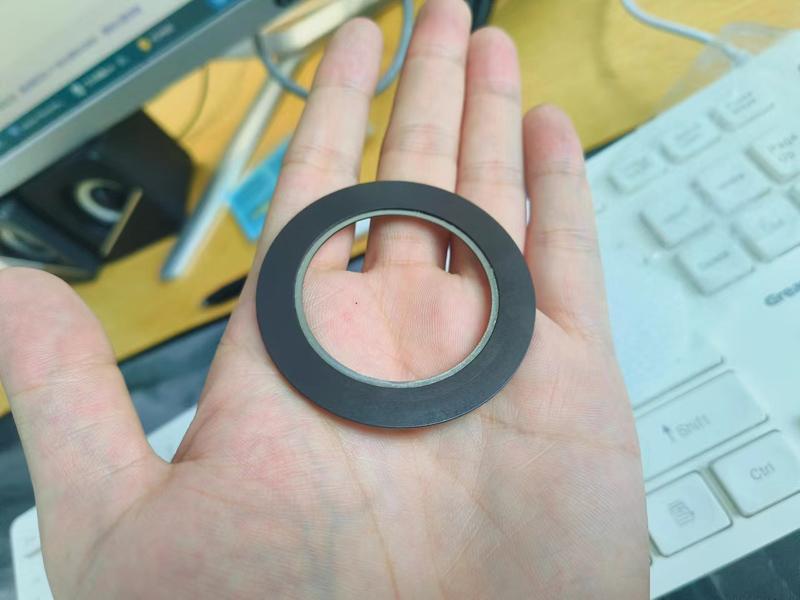

Encoder magnetic ring is a key component in the rotary encoder system, usually consists of multiple alternating N-pole and S-pole, commonly 32-pole, 64-pole, 128-pole, 256-pole, it is used in conjunction with the sensor for accurate measurement of rotary position, speed and direction, in this article, mainly for you to introduce the installation of the encoder ring related.

Ideal mounting position for the encoder's magnetic ring;

Often mounted at or near the end of the rotating shaft, it should be at a suitable distance from the sensor, a distance determined by the specific encoder system specifications.

Encoder multi-pole magnetic ring mounting method:

Directly affixed to the shaft

Press-fit or kit

Use of specialized fixtures

Thin multi-pole encoder rings, flexible rubber material

Precautions for mounting encoder magnetic rings;

Make sure that the selected magnetic ring matches the encoder model. Different types of encoders have specific requirements for the size, shape, and magnetic strength of the magnetic rings.

The mounting position of the encoder's magnetic ring must be very precise to ensure that it is aligned with the sensor. Any offset or misalignment will affect the accuracy of the measurement.

Ensure that the distance between the magnetic ring and the sensor is within the recommended range. A distance that is too large or too small will affect signal strength and accuracy.

The magnetic ring should be firmly fixed in the mounting position to avoid movement or vibration during operation. Suitable fixtures or adhesives may be used.

Installation should ensure the accuracy of the pole spacing and pole pairs to avoid jumping or vibration when the motor is rotating at high speeds.

Magnetic rings and sensors should be installed in an environment that avoids adverse conditions such as strong magnetic fields, extreme temperatures, humidity and dust. These factors may affect the magnetic properties of the ring and the performance of the sensor.

Inspection and calibration are required after installation to ensure that the magnetic ring and sensor system is functioning properly. If necessary, inspections and recalibration can be performed periodically.

The encoder magnetic ring is an important component in the work of the motor, and it plays an important role in the control and measurement accuracy of the motor. When installing encoder magnetic rings, you should choose the correct installation position and direction, and observe the installation precautions to ensure safe and reliable use.

Related Encoder Magnetic Ring product recommendations;

Magnetic encoder multipole ring magnet 62 64 pole OD 34mm

China 64 Pole Pair Magnetic Code Disk Encoder Grid Ring Magnet

Multipole double coil rubber magnetic ring for encoder D49x25x2mm

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier