Sintered NdFeB is a very powerful permanent magnetic material, whose main raw material components include neodymium (Nd), iron (Fe) and boron (B), each of which plays a different role in determining the magnetic properties and physical properties of NdFeB.

Neodymium (Nd)

Role: Neodymium is a rare earth element that plays a major role in NdFeB alloys. The addition of neodymium significantly increases the magnetic energy product (BH_max) of the magnet, which is the amount of magnetic energy that can be stored per unit volume. The presence of neodymium makes NdFeB one of the strongest permanent magnet materials.

Impact: The amount of neodymium content directly affects the magnetic properties of NdFeB magnets. Too high or too low a neodymium content will affect the stability and demagnetization resistance of the magnet.

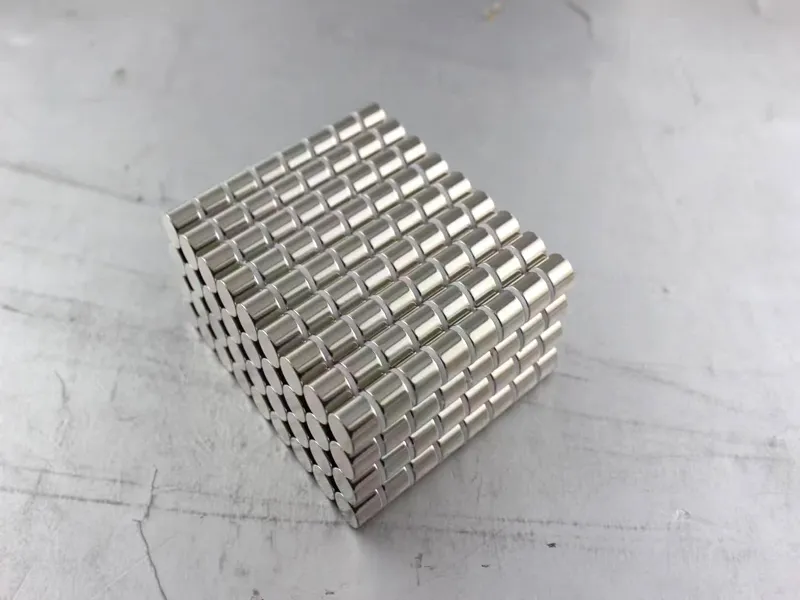

Cylindrical rare-earth neodymium magnets are shown.

Iron (Fe)

Role: Iron is the base material of NdFeB magnets, providing the matrix structure and magnetic foundation needed for the magnet. The addition of iron not only helps to increase the saturation magnetization strength of the magnet, but also increases the mechanical strength of the magnet.

Influence: The purity and content of iron has an important influence on the magnetic properties and corrosion resistance of NdFeB magnets, and too high a content of iron impurities will reduce the performance and corrosion resistance of the magnets.

Boron (B)

Role: Boron plays an important role in NdFeB alloys by forming the Fe2B phase, stabilizing the structure of the magnet, and increasing the coercivity (i.e., resistance to demagnetization) of the magnet. The presence of boron enables the magnet to maintain good magnetic properties at higher temperatures.

Impact: Proper adjustment of boron content can optimize the overall performance of the magnet; too much or too little boron will affect the magnetic and physical properties of the magnet.

In addition to these three main components, other elements such as dysprosium (Dy), terbium (Tb), and cobalt (Co) may be added to NdFeB magnets during the manufacturing process to further optimize the performance of the magnets, especially the stability of the performance in high temperature environments.

Here's an article you might like;

Main composition and proportion of rare earth neodymium magnets

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier