Neodymium magnets are mainly divided into sintered, bonded and injection molded. Previously, we have introduced the difference between sintered and bonded neodymium magnets, and today we would like to introduce the similarities and differences between bonded and injection molded neodymium magnets.

Same points of molded bonded neodymium magnets and injection molded neodymium magnets;

Materials: Whether injection molding or molding, they can both use NdFeB magnetic powder as raw material.

Molds: Both processes require the use of molds to shape the product, and the design and manufacture of the molds is critical to the quality and performance of the final product.

Appliance: NdFeB products produced by both injection molding and molding processes are widely used in motors, sensors, electrical appliances and other fields.

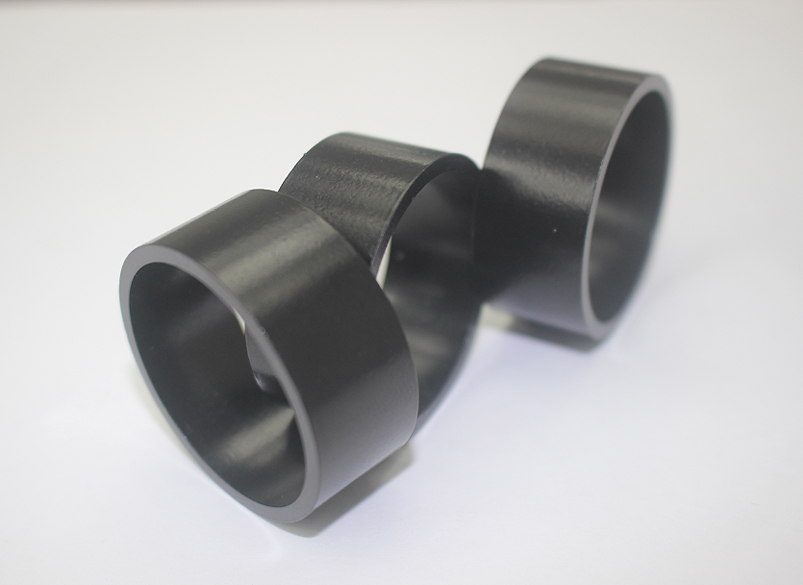

The following picture shows the black appearance of bonded multi-pole neodymium magnets.

Difference between the two

1. Manufacturing process

Injection molding NdFeB: The injection molding process is adopted, where hot-melted NdFeB granules are injected into the mold cavity and cured by cooling to form the desired shape.

Bonded NdFeB: The pelletized magnetic powder is put into the mold and pressed at room temperature. After pressing and molding, it is usually cured at a temperature of about 200° to get the desired shape.

2. Performance and application perspective

Bonded NdFeB: characterized by high magnetic energy product, high coercivity and high coercivity temperature, it is widely used in electronic equipments, automobiles and medical devices.

Injection molded NdFeB: It has the advantages of high dimensional accuracy and high production efficiency, especially suitable for manufacturing magnets with complex shapes.

In terms of magnetic properties, bonded neodymium magnets are better, but also more fragile.

3. Comparison of corrosion resistance

The plastic matrix of injection-molded neodymium magnets provides good corrosion resistance and requires no coating. Bonded neodymium magnets have poor corrosion resistance and generally require the addition of an epoxy coating for protection.

4. Cost aspects

Bonded NdFeB are less expensive because the adhesives used in their production usually cost less than the thermoplastic resins required for injection molding. In addition, the production process for bonded magnets is simpler and does not require complex molds or high-precision equipment.

Injection molded NdFeB and bonded NdFeB have their own advantages and disadvantages, and the choice of which material to use depends mainly on the specific application requirements. If you need complex shape, high precision and good mechanical properties, you can choose injection molded NdFeB; if you need mass production, lower cost and simpler shape of the magnet, bonded NdFeB is a better choice.

Product Selection;

Plastic bonded neodymium magnets

More magnet types to compare;

Neodymium Magnets vs Ferrite Magnets

Rare Earth Neodymium Magnets vs Samarium Cobalt Magnets

Injection molded ferrite vs injection molded neodymium magnets

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier