Our more common magnets with screw holes are round countersunk holes magnets, rectangular countersunk holes magnets, cylindrical countersunk holes magnets, today we introduce you to a kind of arc arc segment screw magnets, like a small part of a ring magnet, you can also call it a half-ring magnet.

Strong arc magnets with screw holes are designed for applications that require a curved magnetic field or a specific mounting configuration that can be mounted on curved surfaces or edges, and used in conjunction with screws, they can be securely fastened to a variety of surfaces or structures.

The materials used for Strong Arc Magnets with Screw Holes usually include Neodymium or Ferrite, with Neodymium being the main material, as the Ferrite material is not as easy to process for screw holes, and it is not like Neodymium Iron Boron which can be processed directly without the need for molds.

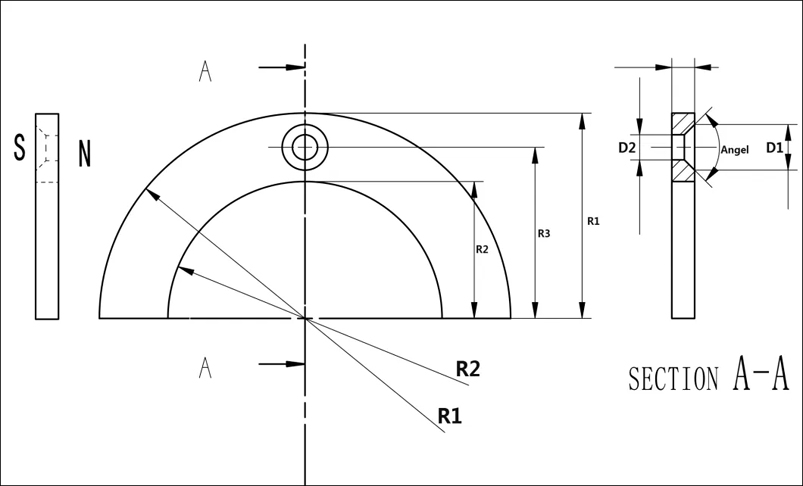

Following drawing shows the dimensions of a curved rare-earth neodymium magnet with countersunk screw holes.

Sample Case:

Height 30mm arc neodymium magnet with countersunk hole

Half Ring Magnet With Two Hole [Custom Price Wholesale]

Curved (arch bridge type) screw holes magnet quintessential application;

1. Electric motors and generators: This is one of the most typical applications for curved countersunk magnets. In permanent magnet DC motors and some AC motors, the curved design allows the magnet to better fit the curved structure inside the motor, reducing the magnetic gap and thus increasing the torque output and efficiency of the motor. Countersunk holes allow the magnet to be fixed to the motor rotor or stator, ensuring stability and safety at high speeds.

2. Furniture and access control systems: In some smart home designs, curved countersunk magnets are used as invisible door suckers or cabinet closing aids, keeping doors or flaps tightly closed with precise magnetic suction, while the countersunk hole design ensures an aesthetically pleasing and unobtrusive installation.

3. Tool and accessory fixing: In workbench, workshop or home maintenance scenarios, curved countersunk magnets can be used as flexible fixtures, such as to attract and hold small metal tools, knives or other accessories for easy storage and access, while the countersunk design allows them to be easily secured to a wall or workbench surface.

4. Industrial Manufacturing: In industry and manufacturing, curved magnets with screw holes can be used to make a variety of magnetic tools and fixtures that facilitate holding workpieces on metal surfaces.

As for the installation, it is still relatively simple, just place the curved magnet with countersunk holes in the desired position and fasten it with screws.

We are a neodymium magnet manufacturer in China, support customized various standard or special neodymium magnets, ceramic magnets, diameter magnetized magnets and so on.

Similar questions;

What screw is better to fix the magnet with hole?

Difference between Straight Hole and Countersunk Hole Magnets

Why ring neodymium magnets need to process countersunk hole shape?

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier