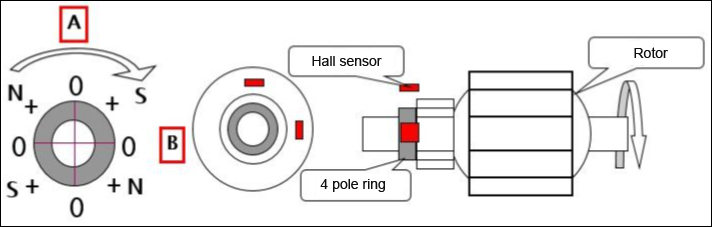

Brushless motor is a type of motor that uses an electronic commutator instead of a mechanical commutator. A Hall element is a sensor commonly used to detect magnetic fields and can be used for rotor position detection in brushless motors. The number of pole pairs refers to the number of rotor magnetic poles in a brushless motor.

In brushless motors, Hall elements are usually mounted on the stator to detect the position of the rotor magnetic poles. By monitoring changes in the magnetic field, the angle of the motor rotor can be determined and accurate electronic commutation can be achieved. The output signal of the Hall element is usually a square wave signal with a frequency that increases with rotor rotation speed.

The number of pole pairs is the number of magnetic poles on the rotor of a brushless motor. For a rotor with N poles, the magnetic field undergoes 2N changes per revolution. Therefore, the frequency of the square wave signal output by the Hall element is directly related to the number of pole pairs. The specific relationship is as follows:

Square wave signal frequency (F) = number of pole pairs (P) × rotor rotation speed (RPM) / 60

Where F is the square wave signal frequency, P is the pole pair number, RPM is the rotor rotation speed (revolutions per minute).

Number of Hall sensors vs. number of motor pole pairs;

The number of Hall sensors is typically configured to be half the number of motor pole pairs, and these sensors are evenly distributed within the motor to cover the transition points for each magnetic pole pair of the motor. For example, if a brushless DC motor has 4 pairs of poles (i.e., 8 poles), it will be equipped with 4 Hall sensors, each spaced at a 90-degree electrical angle (360-degree electrical angle/4 sensors). This layout ensures that the controller is able to accurately monitor the precise position of the rotor during motor operation, and thus switch the current to the different windings at the right time to maintain smooth motor operation and efficient energy conversion.

The number of pole pairs also affects the control strategy and complexity of the motor. Different numbers of pole pairs require different electronic commutation algorithms, such as 120-degree control and 60-degree control. 120-degree control applies three-phase, six-step phase commutation and is suitable for motors with three pairs of poles (six-pole) and higher, while 60-degree control (also known as vector control) provides finer control for high-performance applications, following the rotor position more accurately to achieve near-sinusoidal current control. It is usually more common in high pole-to-pair motors.

When designing a motor, it is necessary to reasonably match the number of Hall sensors with the number of pole pairs in order to obtain the desired control accuracy, torque characteristics and efficiency. Generally, 4-24 pairs of magnetic poles are more common, corresponding to 3-6 Hall sensors can meet the requirements of most applications. A high number of pole pairs increases the control resolution, but also increases the complexity.

Types of magnets commonly used in brushless motors;

Sintered Neodymium Arc Segmented Magnets

Multipole Neodymium Magnets Ring

Related brushless motor magnet knowledge;

Do brushless motor magnets affect motor speed?

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier