Curved magnets in lift traction machines (also known as lifts or lifts) are commonly used as braking and safety devices in lift systems. These curved magnets are a key component of a lift's braking system, and they achieve braking by generating a magnetic field to ensure that the lift is safe and secure when it stops or comes to a halt. The following is an introduction to arc magnets in lift tractors:

Braking principle: The braking principle of arc magnets is based on electromagnetic induction. When the lift needs to stop or decelerate, the lift system charges the arc magnet through the power supply. This causes the arc magnet to generate a strong magnetic field. At the same time, the brake shoes (also known as brake blocks or brakes) on the lift, which are usually made of iron, are located at the bottom of the lift car.

How the brake works: When the lift needs to be stopped, the magnetic field of the curved magnet attracts the brake shoe and brings it into contact with the lift's guide rails or the walls of the lift shaft. This contact creates friction that brakes or slows down the lift car, eventually stopping it in the desired position.

Safety: The safety of lift braking systems is of paramount importance as they ensure that the lift can be stopped safely in the event of an unexpected situation. Curved magnets are used as part of the braking mechanism to effectively brake the lift in the event of a power failure or other emergency, preventing unintended movement.

Electrical control system: The lift's electrical control system is responsible for controlling the energisation and de-energisation of the arc magnets for precise braking and stopping. These systems are usually managed by the lift's controller or electrical control unit.

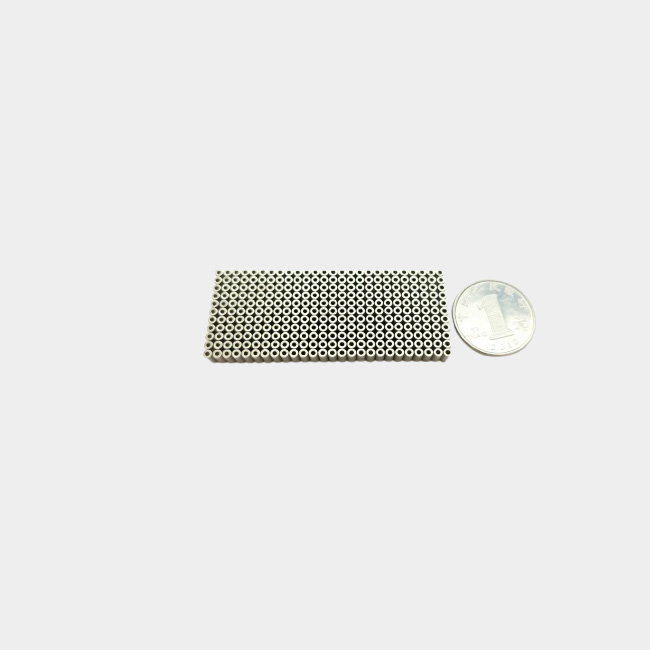

Design Flexibility: The design of arc magnets can be adapted to suit different types and sizes of lift systems, depending on the model and manufacturer's requirements. Different lift applications may require different sizes and shapes of arc magnets.

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier