Buy curved magnets, welcome to contact Courage magnets manufacturer, our company is a professional permanent magnets for motors manufacturer, for the production of curved segmented magnets for motors, multi-pole ring magnets are very experienced, today share about how to choose the right curved magnets.

Here are some buying considerations that I have compiled to help you choose the right curved bending magnet.

1. Requirements for magnetic properties

Clarify the application scenarios of arc magnets, and select the magnetic properties of the tiles according to the needs of different application scenarios, such as neodymium iron boron is suitable for occasions that require high magnetic force, such as high speed motors. While ferrite tiles are suitable for general magnetic force requirements, such as micro motors.

2. Consider the working environment of the curved magnet

The performance of curved magnets made of different materials will be different at high temperatures. For example, NdFeB curved magnets are easy to demagnetize at high temperatures, while Alnico tiles have good high temperature stability. In humid or corrosive environments, it is recommended to choose magnetic tiles that have been treated with anti-corrosion treatment, or materials with corrosion-resistant properties of their own, such as ferrite curved magnets.

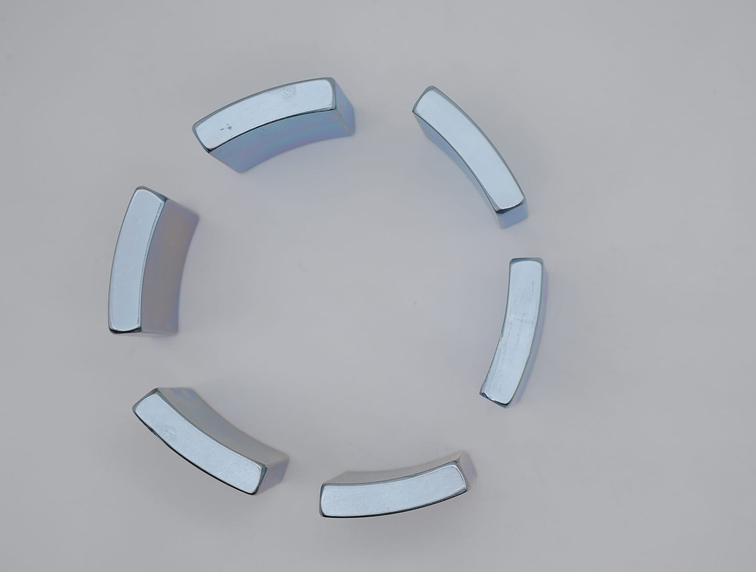

Picture shows galvanized arc neodymium magnets N42H.

3. Size and shape aspects

The size and shape of the bending magnet need to match the installation space and structure of the equipment. For equipment with complex structure, customized special shaped tiles can be considered to ensure the best installation effect and magnetic field distribution.

4. Cost budget

The cost of arcs varies greatly from material to material, and the choice needs to be balanced between performance and cost to ensure that the budget is controlled while meeting the needs of the application. If the demand is high, the cost per piece can be reduced by purchasing in bulk.

5. Note the direction of magnetization of curved magnets

There are several magnetization directions for curved magnets, so you need to check with the magnet manufacturer.

6、Proofing test

Before formal application, it is recommended to test and verify the arc magnet to ensure that it can operate normally and achieve the required effect.

In addition, in the selection of suppliers, product certification should also pay attention to ensure that the quality is over the top.

Related Technical Articles;

Shape Type And Advantage of Magnets In Electric Motors

Why are arc curved magnets mostly radially magnetized?

Biggest difference between curve and rectangle magnets in motors

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier