Often dismantle the DC motor friends will find that the stator of the motor is basically 2 pieces of ferrite curved magnets, this time the network will ask, why is it 2 pieces of magnets?4 pieces of magnets can not? If it is 4 pieces of magnets to remove the 2 carbon brushes can? Will the speed become faster? If the brush DC motor inside the 2 ferrite magnets replaced with neodymium iron boron multi-pole magnets, the motor can still run normally? And so on a series of questions.

DC permanent magnet motors with 2 pieces of magnets are 2 poles, similar to AC motors, such is 2 carbon brushes. There are also four pole ones, so then you need four carbon brushes, most starter motors for 125 motorcycles are four magnets and four carbon brushes. That is, a four-pole. Such motors have lower rpm and more torque than 2 pole.

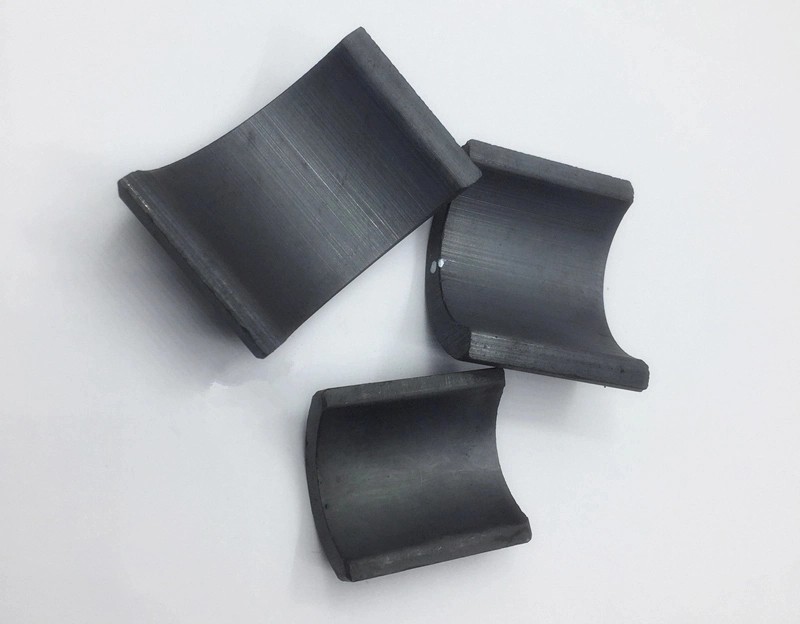

Matching pictures for micro-motor / power tools and other special arc ferrite magnets, cheap!

4 piece magnet has 4 carbon brushes, is it ok to remove 2 carbon brushes?

No, removing a pair of magnets and carbon brushes changes both speed and power.

The original use of ferrite for neodymium iron boron may have an impact on the coil and so on to make appropriate adjustments, because the magnetic force of neodymium iron boron than ferrite is much larger, of course, the main thing is that the cost of ferrite will be increased by a lot, so this is why the selection of ferrite magnets is the main reason.

What is the difference between 2 pieces and 4 pieces of permanent magnet motor stator magnets?

The 4-block magnet has a more uniform magnetic field distribution with four main poles, smoother magnetic field strength and less fluctuation, which helps to reduce torque pulsation and improve smoothness of operation.

In terms of torque output, four (4-pole) magnets have a higher torque output and are suitable for high power applications. More poles provide higher torque with less torque fluctuation.

Efficiency is also higher with 4 magnets because the magnetic field is evenly distributed, which helps reduce electromagnetic losses and improves performance under various load conditions.

Powerful motor tiles of the number of blocks must be more, some or several stacked together, usually ordinary motor with ferrite materials, if you want to high speed and high efficiency, then you have to use neodymium-iron-boron.

Well, today is introduced here, the article belongs to the magnet problem column, there is a need for permanent magnet motor stator magnet remember to contact us Oh.

Motor Stator Magnets Category;

Multipole Radial Magnetic Ring

More stator magnets are introduced;

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier