In the design and manufacture of motors, the advantages and disadvantages of magnetic materials have a crucial impact on the performance of the motor, by analyzing the operating results of the motor, we can assess the quality and performance of the magnetic materials used, the following is the specific content.

1. Torque of the motor

The torque of the motor can directly reflect the performance of the magnetic material. Typically, a higher motor torque means a higher performance of the magnets; a lower torque means the magnets are likely to have a lower performance. In small motors, it is often desirable to have a small positioning torque, i.e., the torque of the motor from standstill to the instant it begins to rotate. This metric is mainly affected by the magnetizing waveform and core slot shape.

2. High and low motor speed

The speed of the motor is divided into no-load speed and load speed. When discussing the relationship between rotational speed and magnetic material performance, the influence of other resistive moments of the motor should be excluded. Generally speaking, the higher the no-load speed, the lower the performance of the magnetic material; on the contrary, the higher the performance of the magnetic material, the lower the no-load speed. Under load conditions, the higher the load speed, the better the performance of the magnetic material; the lower the load speed, it may be due to the poor performance of the magnetic material.

High Performance Radial Multi-Pole Sintered Ferrite Rings

3. Motor Current

The current of a motor is equally divided into no-load current and load current. When discussing the relationship between current and magnetic material performance, the influence of other resistance moments should also be excluded. Usually, a higher no-load current indicates a lower performance of the magnetic material, while a lower no-load current indicates a better performance of the magnetic material. However, this is not always evident in motors, since the magnitude of the no-load current is more related to the resistance of the windings. Higher load currents indicate poorer performance of the magnetic material; while lower load currents are associated with higher performance of the magnetic material.

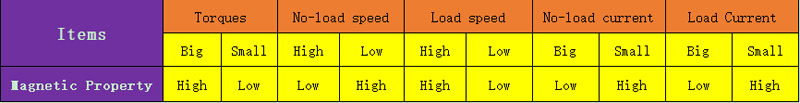

We can illustrate the above relationship with the following table

Conclusion

The three parameters of motor torque, speed and current are interrelated and need to be considered together in order to accurately judge the advantages and disadvantages of magnetic materials. Combining the results of these aspects can help to better evaluate the performance of magnetic materials and thus make the right choice.

Content Similar Articles;

Influence of the size of arc magnets on motor performance

Analysis of the role of magnet thickness on motor performance

China Neodymium And Ferrite Magnets Manufacturer & Supplier

China Neodymium And Ferrite Magnets Manufacturer & Supplier